An overwhelming number of manufacturing execution system (MES) deployments fall short of the finish line; in their wake, they leave partially implemented and, therefore, ineffective solutions. A typical outcome: stalled digital transformation and a budgetary freeze for additional IIoT projects. It’s not an uncommon scenario for MES projects, yet most manufacturing companies seem unaware that many MES deployments fail to hit expectations.

Any manufacturer that can get things back on track can still reap the full value of the original implementation concept. More importantly, it can achieve greater production efficiency, competitiveness, and all the benefits of a modern digital manufacturing facility that applies IIoT technologies and processes improvements. A proven project deployment methodology that includes well-defined contingencies executed by an experienced team is the panacea to overcome project deployment failures.

A Pragmatic MES Plan Assumes and Anticipates Speed Bumps

In principle, a sound MES solution deployment methodology is largely consistent from one manufacturer to another. However, in practice, the execution process varies widely from one company to the next — precisely because an effective methodology will provide for — indeed anticipates — the fact that each organization is unique and operates in a distinct situation. Thus, an effective implementation methodology addresses, adapts to, and accommodates the many unique situational and environmental factors present within each manufacturer’s landscape — a project implementation plan with an intelligent design.

Nevertheless, a proven deployment methodology is crucial for project management, measuring progress, and determining if the project has reached milestones. A well-thought-out project and solution implementation methodology executed by an experienced team expands the manufacturer’s knowledge and level of confidence. In turn, it creates a harmonious, informed relationship that is vital for a successful outcome. It’s a collaborative partnership, armed with an intelligent design that provides contingency strategies and clearly defined processes to handle exceptions that inevitably occur. It’s the antithesis of the ill-equipped team that overlooks exceptions or doesn’t adequately account for them at the project planning stage.

Gathering Machine Data: Plug-n-Play not the Norm

An effective MES deployment always begins with a complete machine connectivity audit (MCA), including all plant assets that are in-scope. An MCA is a highly effective approach to create a dependable, achievable, and realistic project plan with clearly defined milestones. A manufacturing company’s primary goal of an MCA is to determine each asset’s “connectability,” (e.g., machine connectivity), assess current connection state, and capture all relevant machine information. The MCA is the foundational backbone for the subsequent project plan and implementation strategy, and the implementation team intimately weaves it into the fabric of the project deployment methodology.

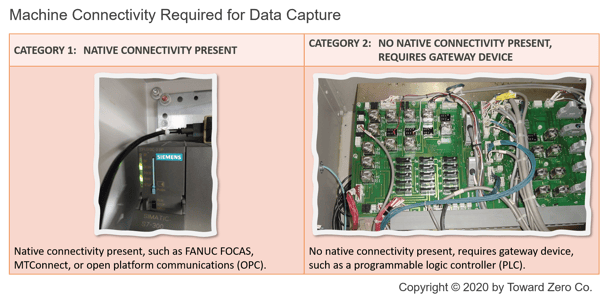

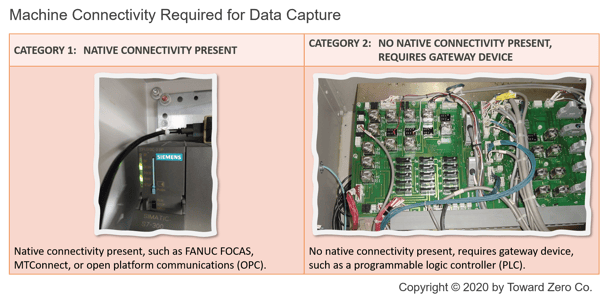

Throughout my career, countless manufacturing executives have asked (incredulously), “You mean we can’t just plug an ethernet cable into the machine to get the data? Why?” Machine connectivity is defined by the type of connection that is supported by the machine builder. Based on this, we divide assets into two main categories. Category 1 assets have some form of native connectivity such as FANUC FOCAS, MTConnect, or open platform communications (OPC). Category 2 assets do not have any type of connectivity and require an IIoT hardware device or gateway, such as a programmable logic controller (PLC). The gateway device connects directly to operational signals within the machine’s electrical system and enables the acquisition of important manufacturing status information in near real-time (in this case, “near real-time” may be milliseconds).

It’s not uncommon for a manufacturing company to require an additional detailed audit of the electrical wiring schematic for each asset along with an ROI assessment. Usually, these deliverables are a valuable gauge to ensure that the effort and costs involved deliver relevant metrics within the production landscape. In some cases, the organization can update the control systems of older “legacy” assets to enable direct connectivity. In any case, the company should assess each Category 2 asset on an individual basis to establish the most efficient connectivity plan overall.

Success Criteria: MES Implementation is Inclusive, Transparent

Once the MCA is complete, and all the machine connectivity data has been incorporated into the project plan, it's time for an implementation kick-off meeting. During the discussion, project leaders brief the entire deployment team and key stakeholders and clearly explain how the project looks as a whole. The conversation should include timeline, milestones, action items, deliverables, and expectations.

At the outset and throughout the entire project, accurate, consistent feedback of current status, exceptions, and all project-related information and communications ensure that everyone is aware of project progress, delays, concerns, and achievements. Every project should have an easy-to-access “single source of truth” for all team members and stakeholders — easy to navigate, up to the minute information, and forward outlook, usually housed in a project management platform. Every project team, team member, and stakeholder should know how to access the project management platform.

As we recall the essential clearly defined contingency strategies, the project management platform is the ideal place to also house the information that will give everyone peace of mind in a situation that could disrupt or derail the project. When an exception triggers the contingency strategy, it should also set in motion a defined action plan to produce a solution. The result is a project within a project to resolve the exception and allow the main project to get back on track ASAP. During the exception and resolution process, up to the minute status should always be available to all team members and stakeholders, ensuring consistent information flow, transparency, and full disclosure.

MES Success is Stepping Stone to Enterprise Digital Transformation

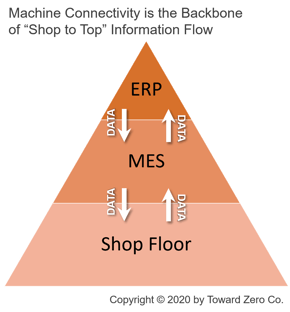

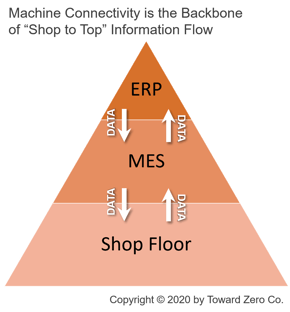

Once deployed, an MES also provides the connectivity backbone or platform for many different manufacturing software systems to collect and share vital data and information — not just making shop floor to top floor, and top floor to shop floor information sharing truly possible, but with greater velocity, variety, and veracity.

As an example, consider the manufacturing organization that had a stalled MES implementation. The company never even got the system running in the pilot plant. By looking to a deeply experienced manufacturing solutions team, it didn’t just get the MES installation back on track. Ultimately, the industrial company established vital bi-directional information flows from order entry and production scheduling to the shop floor, and production information flows back to the ERP system for materials ordering, tooling, and maintenance.

As an example, consider the manufacturing organization that had a stalled MES implementation. The company never even got the system running in the pilot plant. By looking to a deeply experienced manufacturing solutions team, it didn’t just get the MES installation back on track. Ultimately, the industrial company established vital bi-directional information flows from order entry and production scheduling to the shop floor, and production information flows back to the ERP system for materials ordering, tooling, and maintenance.

Getting the MES Implementation Back on Track

While conducting a comprehensive machine connectivity audit is an art form that requires so much more than a detailed plan, it's certainly within every manufacturing company's grasp to succeed with MES deployment. The consequences of failing at MES implementation and adoption aren't just in the plant — indeed, a failed project can ripple throughout the organization to stall digital transformation and IIoT efforts. If your company isn’t willing to risk such dire outcomes, consider these recommendations to get the MES program back on track (or to keep it from stalling in the first place):

- Before there’s a rollout plan, and long before there's even a timeline, think about how your company is going to get data out of the machines. No machine data = no Smart Manufacturing, no factory of the future, no IIoT, and no digital transformation. Even if you conducted a machine connectivity audit the first time around, revisit the report and documents to make sure there’s nothing missing that could have caused the MES deployment to stall.

- If your software vendor tells you that it’s not important to get data out of “all” or even “most machines,” get a second opinion. Look at the problem from a slightly different perspective … yes, your company can monitor the first asset and the last asset in a production line, but what about all the things that happen in between? If a machine in the middle is causing the bottleneck, how will you know which one, and more importantly, why?

- Use a proven implementation methodology, or make sure your solutions partner uses one. The best MES implementation methodology is suitable for most or all manufacturers, has adequate flexibility to accommodate unique differences, and acknowledges and addresses the potential for problems along the way.

- Conduct change management appropriately (and proactively, not after the fact). MES implementation is equally about culture and processes as it is about a software solution, and companies that manage it holistically come out the winners.

As an example, consider

As an example, consider