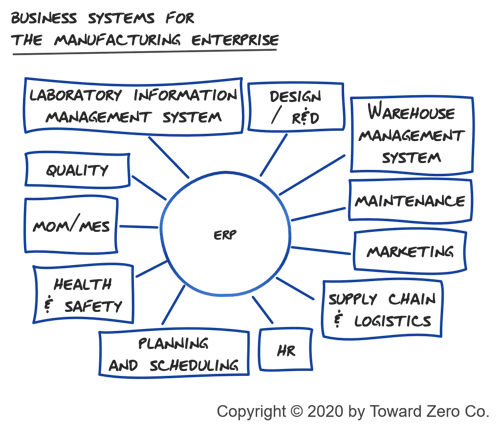

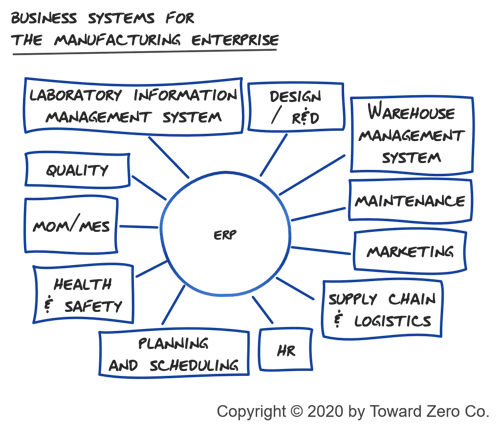

Until recently, nearly every company had an expectation that the manufacturing ERP system should be sufficient to run the business. However, despite the name: enterprise resource planning (ERP), most ERP systems rarely cover all processes enterprise-wide. The reality is that software vendors build them to focus on core operations. The planning capability is typically limited to high-level budgeting while providing placeholders for business users to populate estimates from external sources. In this context, perhaps a more fitting name would be financial resource and document tracking (FRDT) system. To become genuinely enterprise-wide and provide robust planning capabilities, most systems require additional modules, customization, special reports, and bolt-on sub-systems. This approach might initially seem odd. However, it’s quite reasonable once you consider the rationale for designing them this way.

Manufacturing ERP Elements Decoded

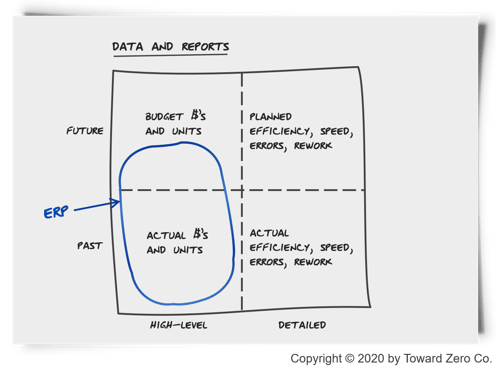

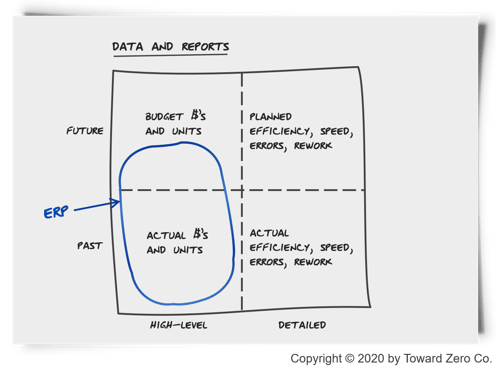

There are three elements to decode. First is the organization’s need for a historical record, which is satisfied by tracking base information across many transactions. Next is the need for audit-quality output, which is achieved by limiting both user options and complexity of calculations. Finally, the organization needs future-oriented complex calculations. This element is counter to core ERP design and therefore other specialized systems are required.

Manufacturing ERP Element 01: Critical Historical Record

At the most basic level, companies need a historical record to document performance and obligations. The manufacturing organization uses these historical figures to track resource utilization and value creation, such as materials consumption into finished goods and finished goods conversion into sales. They also use them to measure performance against pre-established budgets, so managers can monitor variance against expectations and adjust as necessary. The historical data is used as the basis to forecast future performance and identify potential future budget variances.

Most manufacturing ERP systems do a good job of documenting high-level information about the past however, business users need more than just the foundational historical data to do their jobs. Typically, people throughout the organization manipulate these historical figures outside the ERP system so they can leverage intelligence beyond “history repeats itself.”

Manufacturing ERP Element 02: Financial Reporting

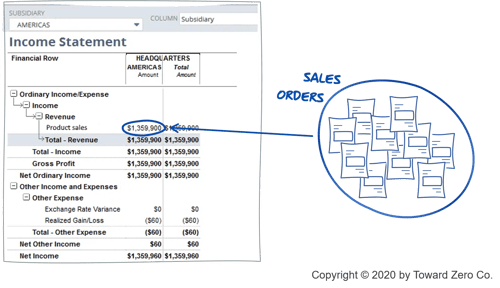

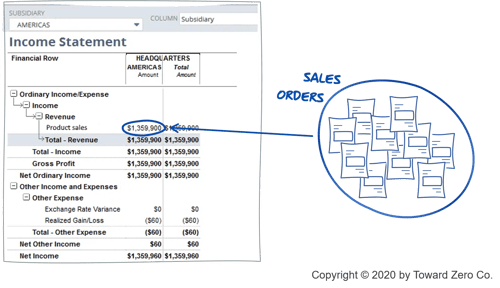

Beyond the historical record, companies need to publish financial statements in a standardized format. Typically, owners, shareholders, investors, lenders, and many other stakeholders require the accounting standard known as GAAP, generally accepted accounting principles. This set of common accounting principles, standards, and procedures specifies accepted ways of recording the major financial statements including income statement, statement of equity, balance sheet, cash flow statement, and supplemental notes. Each of the financial statements is a summary level report of operational information. For example, the income statement's top line is labeled Revenue which is a single dollar value that represents the sum of all the amounts invoiced to customers in that historical period. Every figure on every financial statement comes from adding up the underlying source documents and transactions. Most basic ERP systems strive to protect the integrity and "auditability" of the financial statements by avoiding going too deep into core operations or too broad beyond core operations.

Manufacturing ERP Element 03: Transactions and Documents

Next, companies need to manage all the source documents and transactions.

- Every customer sales transaction typically has an invoice and a cash receipt; they often also include packing slips and bill of lading documents.

- Every purchase from a vendor typically has an invoice and a cash payment; a purchase order and receiving document might also be part of the record.

- As manufacturing consumes raw materials and resources toward finished goods inventory, a production work order specifies the bill of materials (BOM) and the resource routes.

Most ERP systems do a good job keeping all this straight. However, the architecture that makes an ERP system good at tracking the past is exactly what makes it a poor choice for identifying improvement opportunities or predicting the future. That’s because historical tracking systems are designed to summarize a large volume of data in a repeatable format to audit level scrutiny. The information is typically limited to dollars and units. Conversely, forward looking planning systems require more robust calculations that combine changes to historical trends, efficiency calculations, and a host of other information.

Revamp Your Company’s Manufacturing ERP Expectations

No matter what your company’s current initiatives or objectives are, it’s a good idea to take a hard look at how the corporate leadership and department heads view the manufacturing ERP. Some organizations already have a forward-thinking view of ERP as a necessary and foundational element of industrial transformation. Most businesses however still view ERP as the be-all-end-all to run the manufacturing enterprise. Those are the companies that might find transformative efforts cumbersome and contentious.

Ultimately, we’ve consistently seen that companies with a realistic posture toward ERP experience faster and greater overall success in achieving their business objectives. These manufacturers:

- Expect the ERP to be the system of record for financial statements and source transactions

- Don’t look to the ERP system to track detailed activities, processes, and efficiencies unique to the company’s operations or to create robust future targets, plans, or schedules

- Leverage add-on functionality for specialized functions including: customer relationship management (CRM), warehouse management system (WMS), laboratory information management system (LIMS), manufacturing execution system (MES), and many others

- Understand that customization is often required to graduate from rudimentary budgeting to achieve robust planning

- Use forecasting modules to go beyond basic "history repeats itself" planning to incorporate new intelligence, technology, trends, and marketing activities

- Use advanced planning and scheduling (APS) to model the company’s unique processes and efficiencies and dynamically optimize the production sequence in real-time

At the end of the day, let your manufacturing ERP do the job it was meant for: bear the heavy burden of tracking the web of activities and documents as the primary system of historical records. Then, decide which best-of-breed sub-systems your company needs to actually run the business.