Your technology or improvement initiative should help you cut downtime and boost throughput, not get in the way

Plastics and rubber manufacturing companies want better business results. Your technology project should help you do more, make more, and do better. Whatever your transformation motivation is, if the project stalls or fails, it can cost your company much more than just the price tag for licenses or services.

Meet industry pressures head-on and hit performance objectives, so that your business can win its share of new business and grow profits

Plastics and rubber manufacturing are intensely complex markets. As you look for new opportunities to grow revenue and maintain healthy margins, digitally-powered initiatives like operational excellence, continuous improvement, and Lean keep your business strong. Even if the organization is eager for modernization, it might not know where to get started or how to make the gains sustainable.

- Protect profitability despite volatile raw material availability and costs

- Address growing customer demand for quantity and variety

- Free up capacity to capture more business in strong market growth

- Compete against fierce competition, locally and globally

- Head off customer price sensitivity with value-add services and higher quality

Complex pressures common for plastics manufacturing and rubber manufacturing

Every subsector across plastics and rubber manufacturing has its own stressors, and every business has unique challenges. Despite supply chain and workforce concerns, manufacturing companies are eager to embrace technology advances that enable better processes, continuous improvement, and a digitally-enabled workforce. Digital transformation helps plastic and rubber manufacturers address the intense pressure common to every industry sub-sector:

- Ensure your business is flexible and profitable while delivering on customer service

- Get high-quality products to your customers on time and without compromising operational efficiency or margins

- Uncover and act on performance opportunities and ensure gains are sustainable

- Use continuous improvement, metrics, and analytics on the shop floor and in business processes to achieve operational efficiency

- Establish processes and systems to capture and apply tribal knowledge from retiring workforce

- Help you choose the right technologies to serve the business while attracting younger, digitally savvy workers

- Recommend the right mix of technologies so you ensure customer service, increase flexibility, and grow margins

- Juggle complex and operations along with fast-changing order variations

- Reduce waste in production and processes

- Reduce downtime, increase OEE, and achieve optimal production scheduling

- Achieve regulatory compliance and meet industry standards without eroding operational performance or margins

- Eliminate data gaps across legacy “vintage” machines

Plastics and rubber industry companies in every sector trust On Time Edge for digital transformation

Materials manufacturing

The endless use cases for plastics as a preferred material for parts and products across construction, automotive, packaging, and consumer products means that resin manufacturers must satisfy a vast variety of requirements. Material variation can affect end-product quality, defects, and production errors. Your production processes have a significant impact on quality, and can affect acceptance of entire lots of product. Materials manufacturers that want to meet timing and quality requirements rely on operational performance initiatives to stay ahead of the competition.

Injection molding, thermal forming, and blow molding

Injection molding, thermal forming, and blow molding companies operate serve many industries: packaging, consumer products, electronics, automotive, aerospace, building and construction, and others. Depending on which sector your company serves, you might have strict quality and compliance requirements, product demand pressures, or both. Your goal is to maximize every efficiency and quality opportunity to manufacture and deliver highest quality products as quickly as possible.

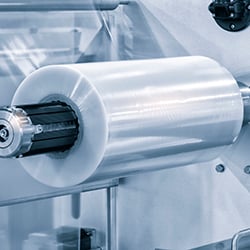

Extrusion

Despite rapid industry growth, tight margins drive extrusion manufacturers to increase productivity, reduce cost, improve performance, and maximize profit. Uptime, waste, yield, and raw materials optimization are what matter most. Shop floor analytics, quality systems, and other smart manufacturing technologies can help extruder operators keep track of failures, so they can focus on maintenance and other factors to prevent unexpected downtimee

Tool and die manufacturing

Despite inexpensive and efficient processes, tool and die companies face complex challenges. Digitalization, scarcity of workfoce, shifting market and customer requirements, and heavy utility consumption are common concerns among tool and die manufacturing companies. Add in raw materials availability and price pressures, and tool and die companies are eager to capitalize on operations performance improvements.

CNC machining

Smaller but more complex and varied lot sizes, demand for greater precision, and quality pressures, make running a CNC operation more challenging than ever before. These factors may mean intricate engineering and re-engineering of parts, process variation for alternate materials, and premature tool wear or failure. The result can be bottlenecks and a less-than-efficient operation that affects on-time delivery, overtime, re-work and other operational metrics. High-precision contract manufacturing means that plastics companies with CNC machining processes don't have the luxury of time to dial up performance during job runs. Instead, they must focus on establishing a repeatable general process so they can quickly and efficiently switch between contract jobs.

Services and solutions that fit your business today and meet your needs as they evolve

Every plastics or rubber manufacturing company has a unique mix of operating environment, industry concerns, and customer requirements. On Time Edge helps you increase revenue and profitability in a way that’s right for your business.

Injection molding, thermal forming, extrusion, materials manufacturing, and tool and die manufacturing have vastly different processes, pressures, resources, and capabilities. What they all have in common is the desire to use operations as a way to improve the bottom line. However, the path to operations performance is unique for every single organization.

Get the value you expect from digital transformation, quickly and sustainably.

Digital transformation is our business. We are experts at deploying and integrating supply chain solutions and smart manufacturing systems – on time and within budget. The result is fast time-to-value and sustainable business value.