Manufacturing companies are still eager to use OEE. Some industry analysts say that it's “dead,” but not everyone in manufacturing agrees. Yes, it’s high-level, and as a standalone metric it’s not particularly actionable. However it’s also a powerful measurement that nearly anyone in a company can quickly digest and use as a starting point to uncover why things aren’t going the way they’re supposed to. That’s not to say that OEE hasn’t been the subject of significant debate — and even angst — since it first made an appearance in Seiichi Nakajima's 1982 book TPM Tenkai. (later published as Introduction to TPM: Total Productive Maintenance, also by Seiichi Nakajima).

Proponents say it’s the only baseline metric that takes into account all the key impacts of manufacturing performance that manufacturers can use on any process. Detractors argue that the metric is only as good as the input for it, that the people calculating or reporting it can do so in error (either knowingly or inadvertently), and that it simply doesn’t mean anything on its own. Statements on both sides of the debate are equally valid.

Our Position on OEE Isn’t Radically Different

That’s correct — we think both sides of the OEE fence are right, but we also know there’s so much more to the story, because we’ve seen it play out hundreds of times, in nearly every industrial setting you can imagine. And, it’s those OEE case studies and experiences that clients seek from us first and foremost. Before clients ever get around to asking us about OEE, they do their homework — a lot of it. After all, they’re usually among the brightest, most educated engineers and managers in the industrial sector. They come to the discussion armed with experience, well-read on the topic, and most of the time having already tried to apply OEE in their operations with varying degrees of success.

What they’re usually looking for from us is insight about how other companies have successfully applied OEE, and the ‘secret sauce’ to making it work. They often discover the answer for success in a combination of the questions they ask, plus answers to the ones they don’t. If you have a question about OEE that’s not covered here, let us know. We promise to update this article to include your question about OEE — whether we know the answer or not. After all, we didn’t coin these insights; we’re simply reporting what we’ve learned over the years from working with manufacturing companies and operations teams.

Three OEE Questions Clients (Almost Always) Ask

Question #1: Can you help us improve OEE?

It’s the most basic of all the questions, and sometimes it’s the hardest to answer. We’ve even had executives ask this, even if s/he didn’t precisely know what OEE is or how to calculate it. They just know higher OEE is “better.”

The short answer: Yes, absolutely any company or plant can improve OEE. That doesn’t mean OEE is the right metric for your organization. There might be other improvement opportunities that are quicker, easier, and hold greater value that your company can or should tackle first. Before any company embarks on an OEE project, we recommend that it first conduct a value assessment of that effort (and the reward) in context of processes, the technology infrastructure, and culture, and compared to other opportunities.

Question #2: How do we calculate OEE for the entire company?

The honest answer: OEE is an indicator of how an asset, line, or work cell is performing; it’s not meant to assess an entire plant or enterprise. With that in mind, it is useful to benchmark equipment, lines, and cells throughout the facility and across the enterprise, particularly in the effort to solve problems or extend best practices. Ultimately, the goal shouldn’t be calculating OEE for the plant or enterprise.

For OEE to be an effective tool in benchmarking and best practice sharing, the company should normalize the calculation across the enterprise, all plants, all processes, and all lines or cells.

The next step is to establish the baseline (or starting point) OEE by line, cell, or even at the machine level. After that, the organization should measure it consistently (real-time, hourly, daily, etc.). Of course, this is only the “measure” part of the effort; to achieve performance improvement, the company and the culture must align and commit to uncovering the reasons for the results or changes, good or bad. In other words, OEE is just noise without a continuous improvement process in place and root cause analysis to back it up.

Question #3: What is the best OEE software for manufacturing metrics?

While the goal is the same for every manufacturer (achieve desired business results), the path to get there varies wildly. There is no “one size fits all” or “best solution.” Again we always recommend that companies start exactly where they are, take stock of their existing processes, technology stack, and culture, and then define a short-term and long-term vision for improvement. One company might find measuring OEE manually perfect for the short-term while operations leaders and company management focus on nurturing the workforce to improve culture. Another company in the very same industry with similar objectives might need to take a step back and examine how it has production lines configured, and not worry about tech or even new metrics until it irons out the production flow. Still another company might benefit most by skipping forward to implement an advanced cloud OEE solution like manufacturing execution management (MES). In every case, it takes thoughtful consideration about what is in place currently, how it’s being used, and if there are quick, simple opportunities for improvement available.

Four OEE Questions Clients Never Ask (but Should)

The four questions companies should also ask are perhaps even more important than the ones they pose. Of course, the answers depend entirely on the current state across culture, technology, and processes plus the vision and business objectives.

MISSING QUESTION #1: Can our culture adopt and embrace OEE as a key metric and create sustainable results?

MISSING QUESTION #2: Do we have the right infrastructure to accommodate and sustain OEE software?

MISSING QUESTION #3: What kind of readiness preparations and training do we need before an OEE solution in place?

MISSING QUESTION #4: Should we start with a simple or comprehensive OEE solution?

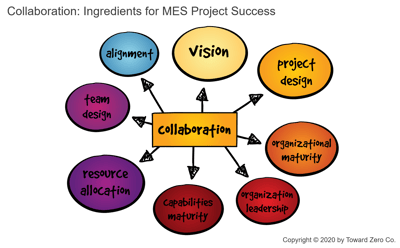

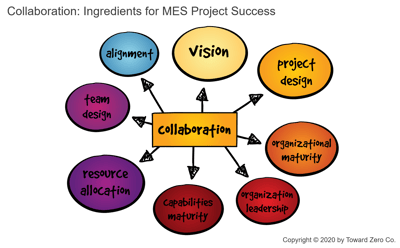

None of the answers to these questions are cookie cutter. That’s why so many companies struggle with OEE — beyond the formula, it’s an extremely complex topic that depends entirely on each manufacturer’s unique situation. It’s also part of the reason a few prominent consultants and industry analysts downplay or flat out reject OEE as a useful metric. In our experience, it’s a powerful gateway measurement that opens the door to explore underlying reasons for performance shortfalls. This metric is working for hundreds of plants among our clients — what they all have in common is carefully aligned culture, processes, and technology, along with leadership vision and support to set priorities and put the right resources behind the right problems.

Getting Started with OEE the Right Way

Manufacturing leaders that are successful using OEE didn’t just wake up one day and suddenly start using it. Like any worthwhile initiative, they took steps to position the organization for success. These basic steps are necessary for every company eager to try OEE.

STEP 1 | Know what the corporate objectives are and commit to align the improvement program to support them. If the top brass hasn’t articulated the business goals and financial metrics, seek out that information first.

STEP 2 | Evaluate the culture — yes, at the operations level, but also between shop floor and top floor, and among departments. If people and departments are willing and eager to work together, that positions the metrics program for success.

STEP 3 | Take stock of the technology infrastructure, supply chain strengths and challenges, and the nuances and supporting details around sales, HR, and other departments and functions.

STEP 4 | Figure out which improvements will have the quickest and greatest impact, then prioritize them from easiest to implement to hardest. Most of the time, it’s quick early wins that ignite and inspire enthusiasm for the improvement initiative.

Of course, the improvement program must be thoughtful and deliberate, and the foundation must include formal assessments, benchmarking, cost/benefit analysis, priority setting, timelines, and a plan for sustainability. Even companies with deeply experienced operations leaders struggle to get the OEE ball rolling. Sometimes it takes an objective third-party to help sort through all the great ideas, conflicting priorities, and typical day-to-day pressures to clear the way for OEE success. Whichever approach your company takes, the most important thing is to provide everyone with a good understanding of what “good” looks like and how the company is going to achieve it.